ROCHESTER HILLS, MI

FANUC America, the world leader in CNCs, robotics, and ROBOMACHINEs will demonstrate a variety of robots, cobots and industrial automation solutions for the woodworking industry at AWFS 2023, July 25-28 in Las Vegas, in booth.

FANUC CRX-10iA/L Sanding Bamboo Cutting Boards

The CRX-10iA/L will simulate sanding small bamboo cutting boards. First, the CRX-10iA/L will use an OnRobot VGC10 vacuum gripper to pick a board from station one and present it to an orbital sander which then simulates sanding the edges. The CRX stacks completed boards at a second station. Once all the boards are sanded and placed in station two, the CRX returns them to station one and the cycle repeats. At the pickup and drop-off stations, the CRX uses FANUC'sTouch Skip software option which can detect the work piece location without any external sensor.

CRX collaborative robots are reliable, flexible and can run for eight years without maintenance. Easy-to-use interactive programming allows operators to teach points using hand guidance or a Tablet TP with drag and drop icons.

FANUC recently expanded the payload capacities of its CRX and CR cobot lines to handle products from 4kg to 50kg. With 11 model variations, FANUC’s cobots can work in a variety of applications including assembly, inspection, material handling, packaging, palletizing, sanding, welding, and more.

FANUC M-10iD/12 Robot Sands Chair Seat

A FANUC M10iD/12 robot picks a chair seat and places it onto a fixture using the FS-15iA Force Sensor’s phase matching option allowing the robot to align and match the chair seat to the fixture. Next, the robot flips the tool and sands the top surface using the Force Sensor’s contour option enabling the sander to apply constant force – this is especially useful for uneven surfaces. Once the robot sands the top side it picks up the seat and places it bottom-side up in the fixture for sanding using the same technique. Once both sides are sanded the robot transfers the seat to a glue nozzle to simulate gluing. Finally, the robot places the seat back on the chair, performs a variety of dance moves, and the cycle repeats.

FANUC P-40iA Robot Paints Guitar

A P-40iA paint robot equipped with the R-30iB Plus Mate controller will demonstrate painting a wooden guitar body using coordinated motion with a turntable, which means that the robot will control the motor that rotates the part on the turntable. The robot will paint the part as it rotates a full 360 degrees, allowing coverage on all sides of the part.

The P-40iA robot has a 1,300 mm reach, 5kg payload, and a compact arm design that fits into small work areas. It offers a cast aluminum body, purged and pressurized arm, FANUC’s purge module, and integrated solenoid valves for gun trigger. Whether the application calls for liquid, powder, FRP chop or gel, the FANUC P-40iA is ready for any applicator and application equipment, making it a complete solution for painting.

In addition, the P-40iA robot can be mounted in a variety of positions including floor, invert, wall or angle mounts to accommodate small or narrow workspaces. Also, the P-40iA can be programmed offline using FANUC’s PaintTool robot software.

FANUC has designed and built its paint robots in the U.S. since 1982 at its headquarters facility in Rochester Hills, Michigan. Learn more about the P-40iA.

Industrial Automation Demonstrations

FANUC will highlight its latest Industrial Automation products, including:

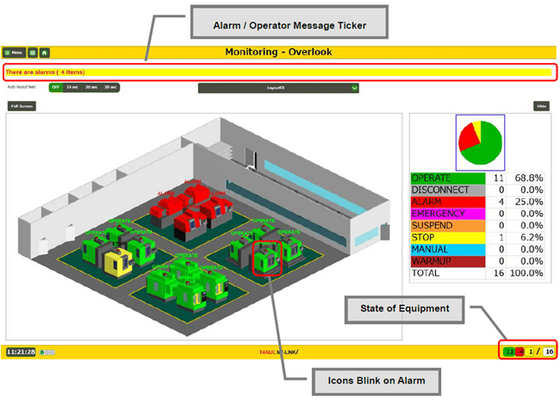

- MT-LINKi , a fully scalable, out-of-the-box machine tool monitoring solution that can monitor, collect, and manage data from one to two thousand machines.

- FANUC’s high-performance CNC and servo systems seamlessly integrated with a Laguna iQ desktop CNC router. Equipped with a complete FANUC CNC system, the display shows how well the machine, control and drives all work together to bring unbeatable value in reliability and accuracy.

FANUC America Corporation PR contact:

Robotics: Cathy Powell

Public Relations and Communications Manager

FANUC America Corporation

T: 248-377-7570

E: cathy.powell@fanucamerica.com

Factory Automation: Debra Schug

CNC Strategic Communications Specialist

T: 847.898.5673

E: debra.schug@fanucamerica.com